Evolubox® Clean Room cell revolutionize your productivity.

Need help?

Specify a keyword related to an offer, a sector of activity, a blog article or any content present on the R&D Technology site

Staying competitive requires transformation. To win, you have to move fast, really fast! Companies no longer have the time or resources to leave repetitive tasks in their processes.

In today’s industry, eliminating repetitive tasks is a major concern, both in terms of economic efficiency and the physical and mental well-being of workers. Constantly performing the same actions can lead to muscle fatigue, tension, and contribute to the development of Musculoskeletal Disorders (MSDs), such as wrist, elbow, shoulder, and back issues. Let’s not forget that humans naturally dislike monotony. Continuously performing the same tasks can lead to boredom and impact motivation, job satisfaction, and mental health. These monotonous tasks are common in industry and often result in workplace accidents, human errors, and production delays.

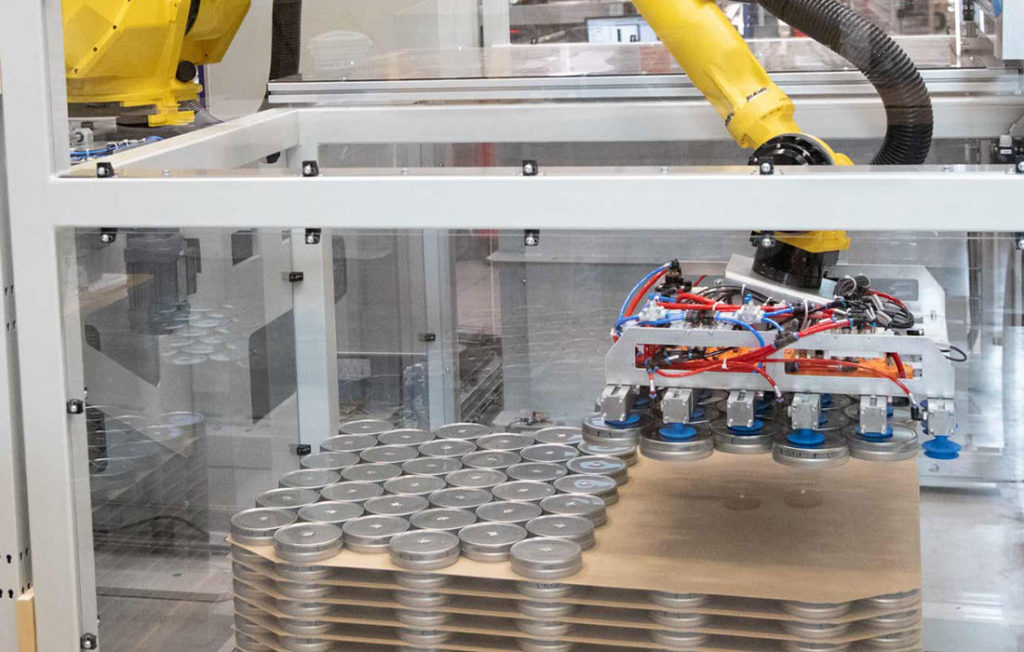

Integrating humans with automated production equipment is a key success factor! This synergy aims to optimize operational efficiency by leveraging the advantages of automation while capitalizing on the unique and creative skills of humans. These technological advancements naturally pose new challenges, such as staff training and skill development, but they also promise opportunities and a dynamic, stimulating future for companies and individuals who can adapt.

We live in a world of immediacy! Influenced by technological advances, the internet, social media, and globalization, consumer demands are constantly evolving and impacting manufacturing…

High-performing companies embrace learning and adopt a proactive mindset.