Eliminating Repetitive Tasks. Do We Really Have a Choice?

Need help?

Specify a keyword related to an offer, a sector of activity, a blog article or any content present on the R&D Technology site

For small and medium series, assembly is usually performed on dedicated manual stations. While the initial investment is low, these setups have proven to be costly over time due to limited flexibility and operational constraints.

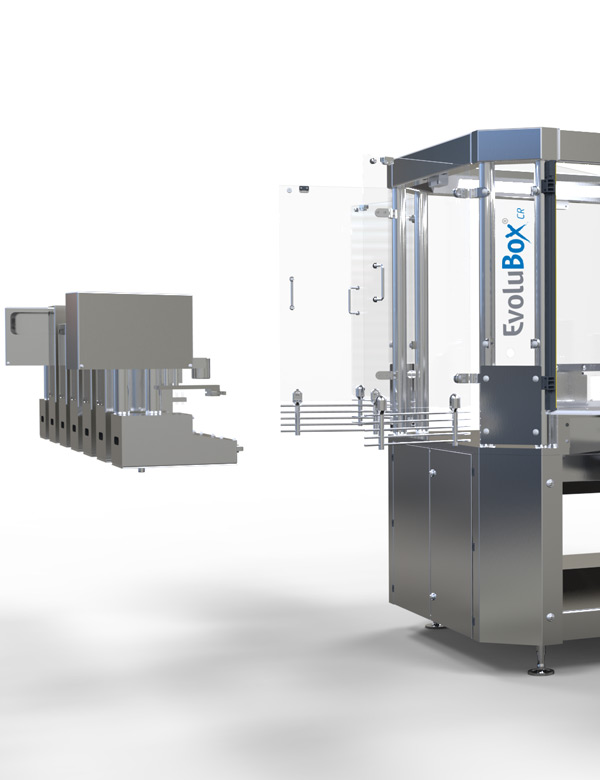

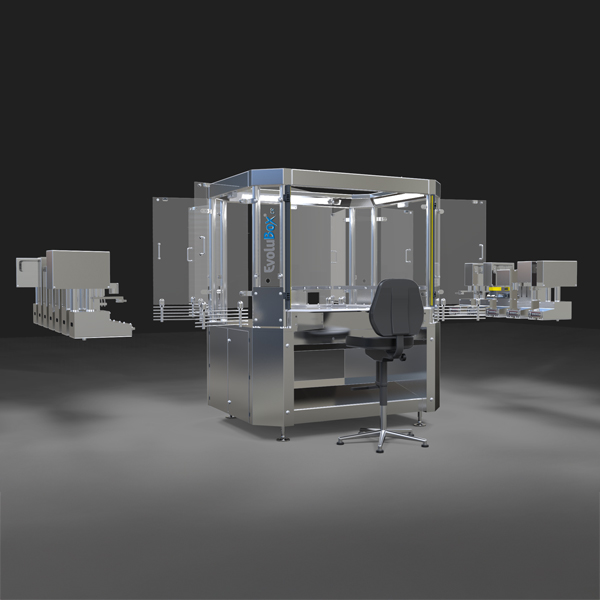

The result of a technological challenge, our EvoluBox® cells open a new path for automated assembly. They offer unmatched flexibility and scalability, allowing rapid transitions from one product model to a variant or even to a completely different product through fast workstation changes.

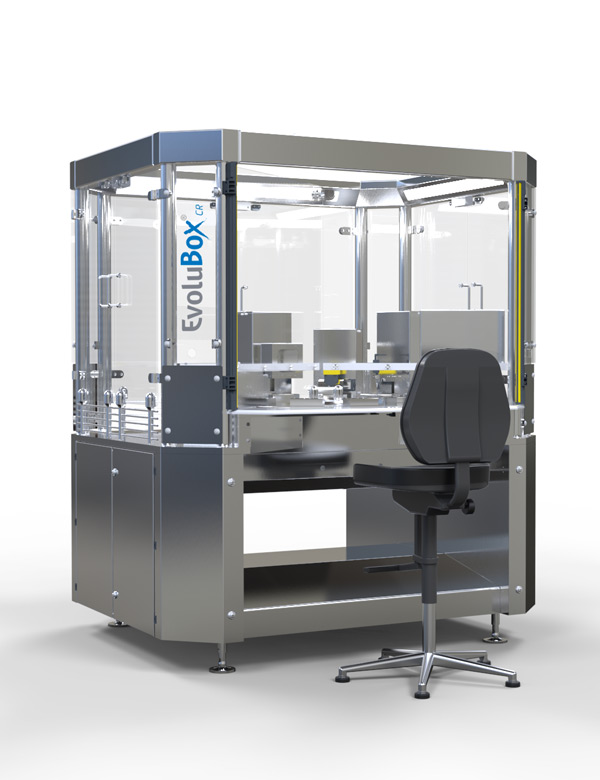

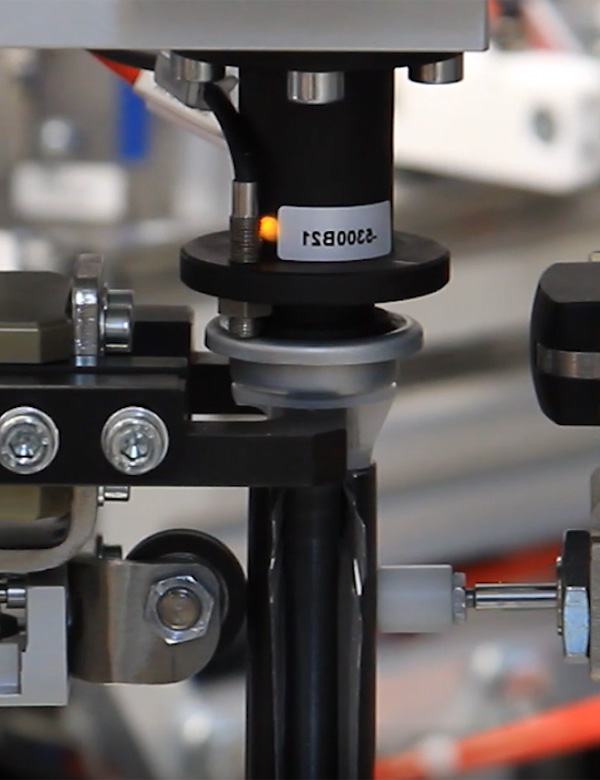

The EvoluBox® Flexible Assembly Unit is made up of a standard 8 or 16-position revolving table insert supporting use of interchangeable automated workstations and configurations.

EvoluBox® Clean Room automates several successive operations to be performed on your parts or sub-assemblies. The stations can perform assembly, marking, packaging operations... What are your needs? Let’s discuss.

The design of the structure takes into account the requirements of accessibility, cleanability and the qualification of ISO 7 rooms.

Thanks to the EvoluBox® Clean Room concept, it is possible to recoup the investment over several products, considerably reducing the payback period.

Equipped with a unique technology, our flexible assembly cells adapt to your real production needs. As quantity requirements increase, workstations can be added to increase the degree of automation. This evolution can go as far as complete automation.