Project details

Product

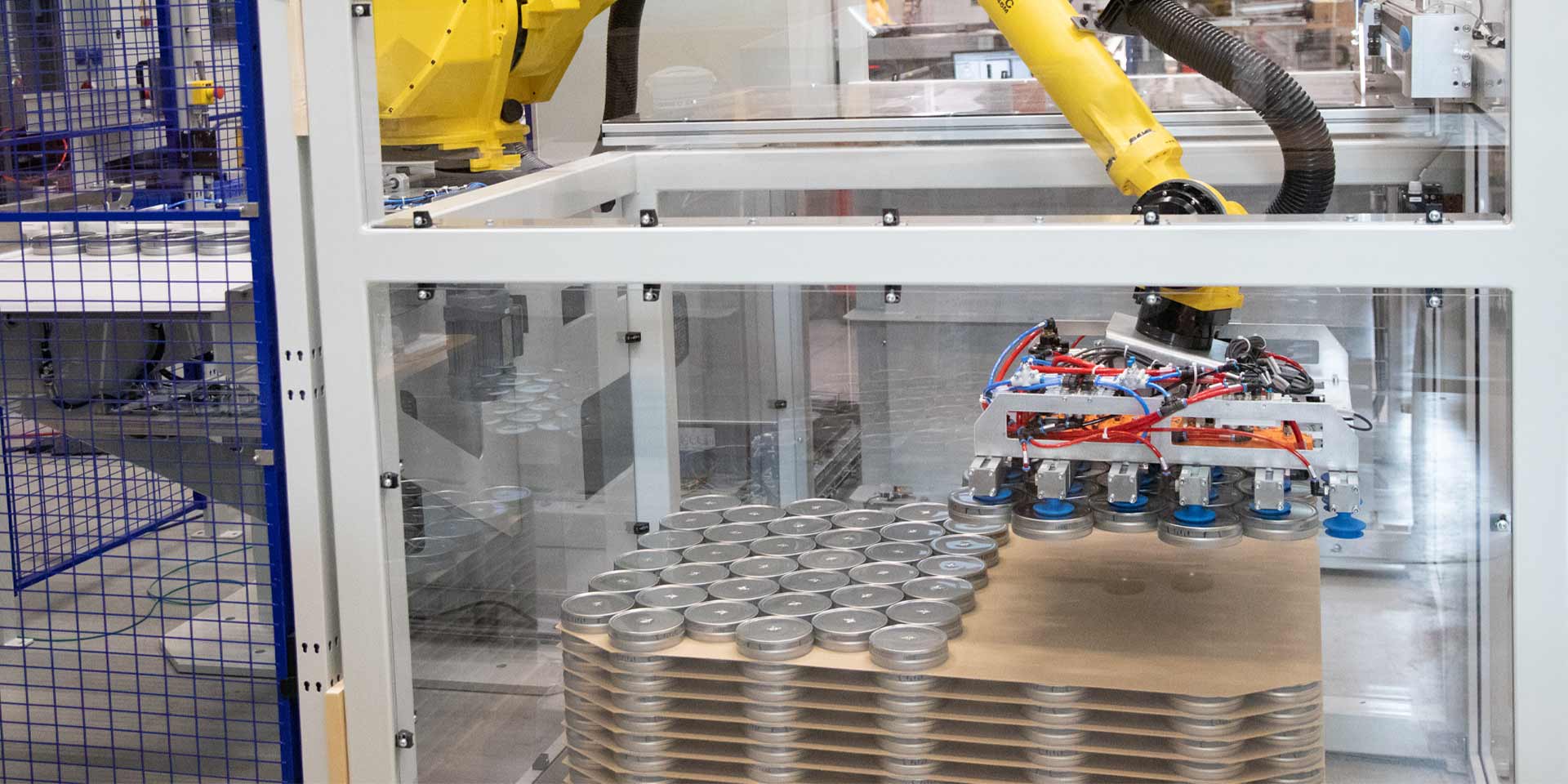

Tin with lid containing flea collars for dogs/cats

Need

Automatic palletisation of tins

Special features

At the end of the production line

Features

- Palletisation of tin bases + lids

- Placing of spacers between each layer of lid/tin bases

- Change of product pallet without stopping production

Rate

100 pieces per hour

Discover the equipment on video