Project details

Product

Accessories for building closure (windows, gates, etc.)

Need

Design and manufacture of equipment for drilling, tapping, counterboring and chamfering of metal parts

Special features

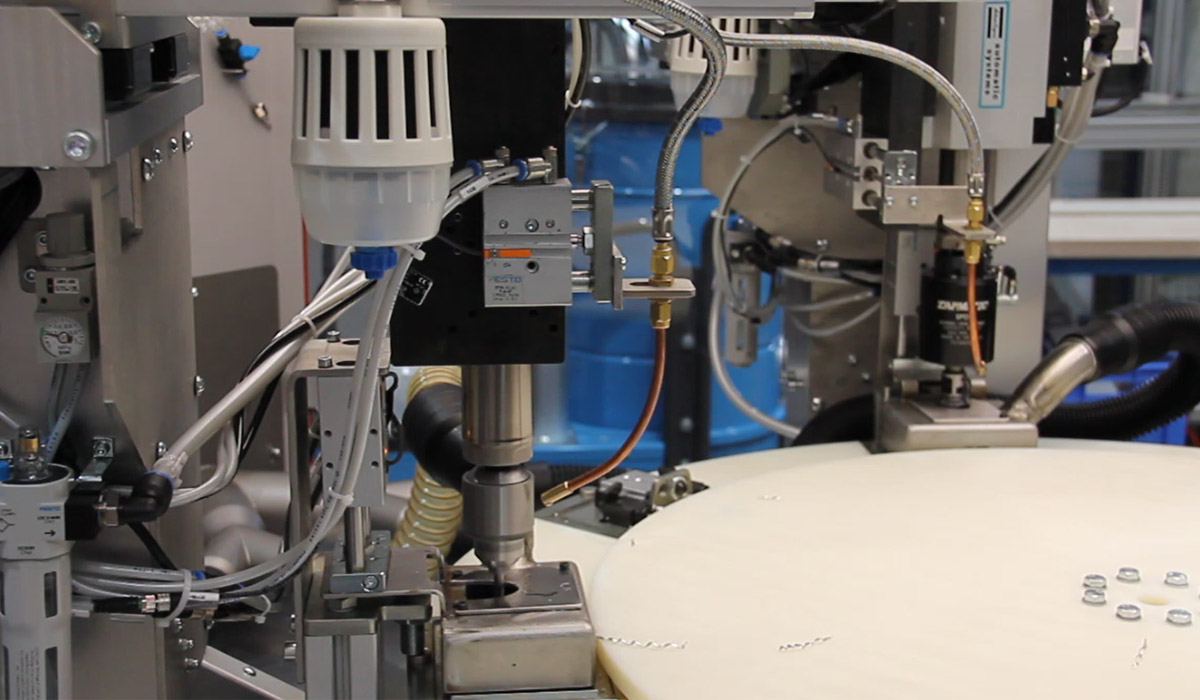

- Based on Evolubox

- 2 pneumatic drilling units + 1 pneumatic tapping unit

- Suction controller/unit

- Micro-spray lubrication

- Ergonomic design of the workstation according to the client's needs

Features

- Multi-product equipment

- Quick removal and referencing of parts by the operator during positioning

- Locking of mechanical parts at each operation

- Suction of chips and excess lubricant and collection in an industrial suction unit

Rate

200 pieces per hour

Discover the equipment on video