The world's smallest book printer with the largest catalogue

Founded in 2019 and located in the city of Nevers, Gutenberg & CO approached R&D Technology to bring to fruition its project to “uberise” the manufactured book sector.

The ambitious start-up aims to revolutionise its market by addressing the following issues. How can the 45,000 new books published each year in France be made available to readers? And what about all the books already available? How can we enhance the value of the editorial collection? How to ensure a permanent and ongoing exploitation of the works? How can literature be made ever more accessible in 21st century society?

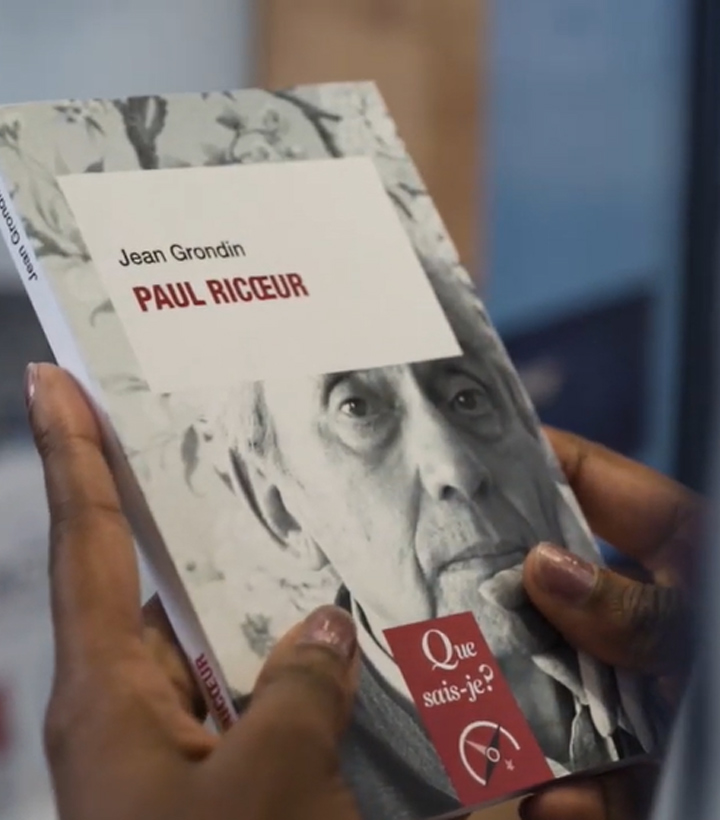

Gutenberg OneTo develop an automatic printer that can produce a book at the point of sale in a few minutes!

Gutenberg.one, a patented invention

Starting with simple elements, ideas and sketches, R&D Technology and Hubert PÉDURAND (Gutenberg & CO project leader) set the innovation cycle in motion with the “Innovative Technology Project – Offer”.

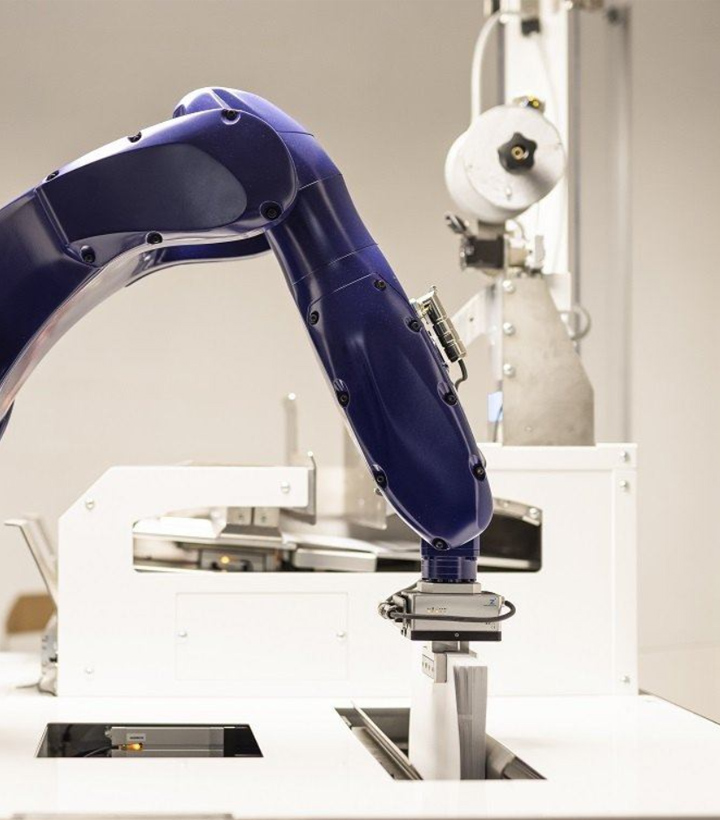

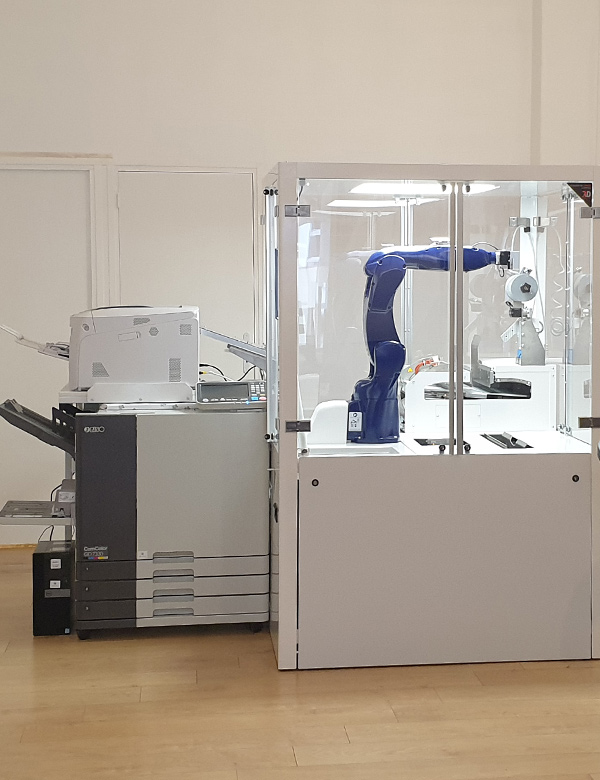

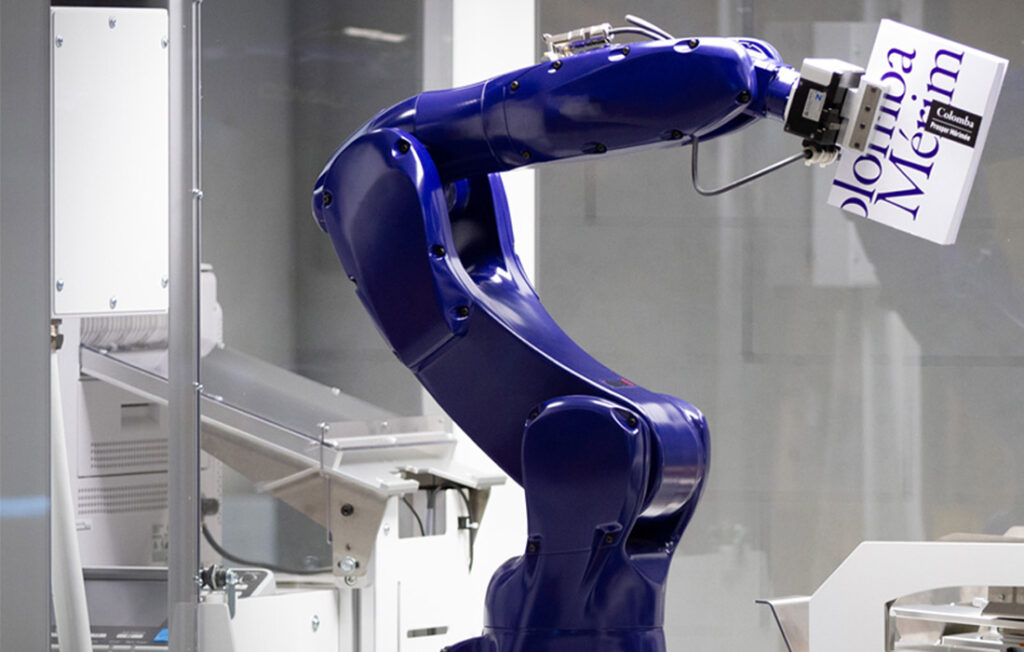

The expertise of our teams quickly focused the project on a robotic solution for the development of the automatic printer. The aim was to reduce the footprint of the equipment as much as possible so that it could easily be set up in bookstores, while at the same time simplifying its overall design. The choice of a robot made it possible to carry out several tasks with the same tool in a reduced space.

We also chose to adopt an open robotics solution (and not to integrate a robot bay) so that we could customise its programming and thus increase its flexibility.

Gutenberg.One is an innovative printing system that allows the production of a single book in front of the customer, brings the book industry into the 4.0 era, and is the result of this collaboration. This solution represents an immediate response to booksellers, offers a wide choice of titles to readers and visibility to publishers, while eliminating the delays and costs associated with storage and logistics.

Discover the equipment on video

Focus

-

Glue application, a surgical operation

In printing, the adhesive is applied to the text block with a roller and then assembled. On Gutenberg One, we surgically apply the adhesive to the cover using an innovative process. Our challenges were to find the right adhesive for this new type of process and to ensure that it was applied to the cover.

-

A printing, folding, stitching and trimming robot

It was necessary for R&D Technology to understand the purpose of every operation that can occur in printing – operations such as grooving, notching, etc. – and then optimise them.

-

A solution that adapts to different sizes

There is no need to change the configuration of the equipment to accommodate different book sizes. A calculation ruler has been integrated so that the robot automatically adapts to the ordered dimensions.

-

Accompaniment to the Book Fair

Gutenberg & Co and R&D Technology presented the prototype to the general public at this event. A real surprise for all those visiting the stand, this occasion also led our teams to take up challenges related to transport and installation.

-

First commissioning in the Harmattan bookshop

Based on its first experience at the Salon du Livre, R&D Technology and Gutenberg & Co took advantage of it by integrating the latest desired improvements to give birth to an industrial version of Gutenberg One. The first automatic printer is now installed in Paris in the Harmattan bookshop.