Feeding an existing automated line

Robotics and cobotics (collaborative robotics) are expanding in the pharmaceutical industry to meet the challenges of performing dangerous, precise, arduous or repetitive tasks, thereby increasing productivity while limiting the risk of MSDs (musculoskeletal disorders).

Given this context, R&D Technology and a pharmaceutical group co-developed an innovative solution for the robotic loading of glass cartridges to feed an existing automated line that used to be loaded manually.

Project details

Product

Glass vials

Need

Robotic loading of glass cartridges to feed an existing automated line

Special features

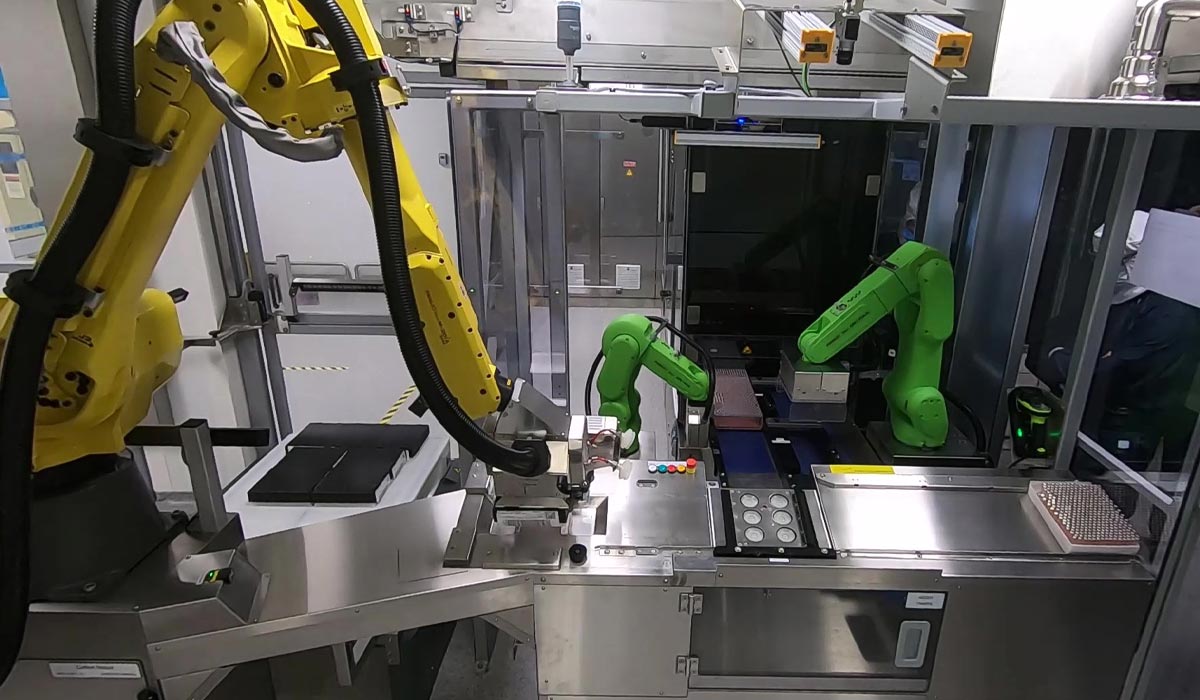

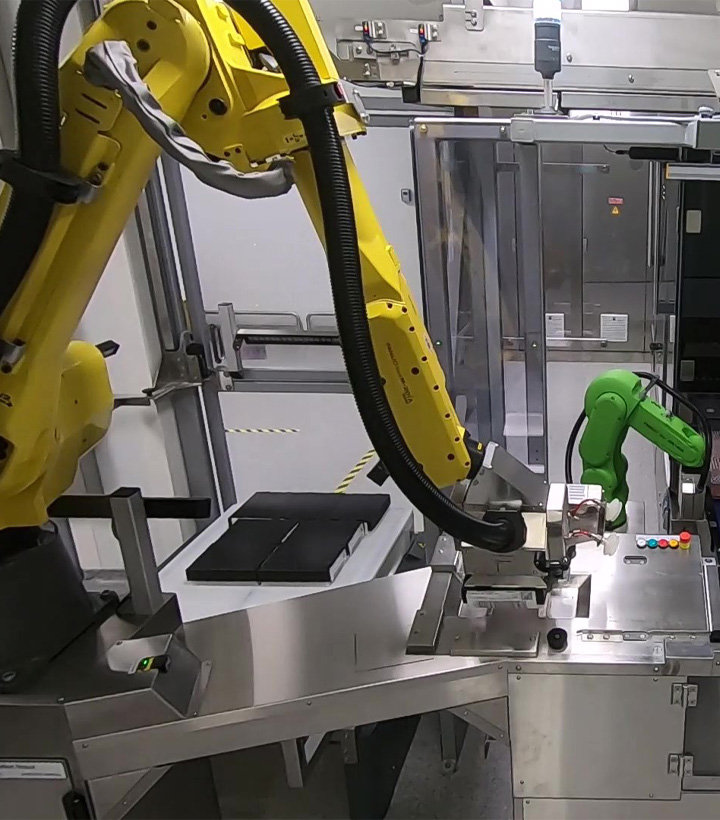

- 1 robot + 2 cobots

- 3D camera

- Artificial intelligence

- Multi-field laser scanner system

Features

- Pallet pick-up of trays

- Barcode reading of trays

- Label cutting

- Opening the trays

- Checking the contents

- Loading glass cartridges

- Removal of lids and trays

Rate

330 bottles per minute

Equipment consisting of one robot and two cobots.

The operations of the first robot start with picking up the trays containing the cartridges from the pallet using a 3D camera. The robot then reads the barcodes on the trays, cuts the labels linking the lid and the base of the trays and removes the lid.

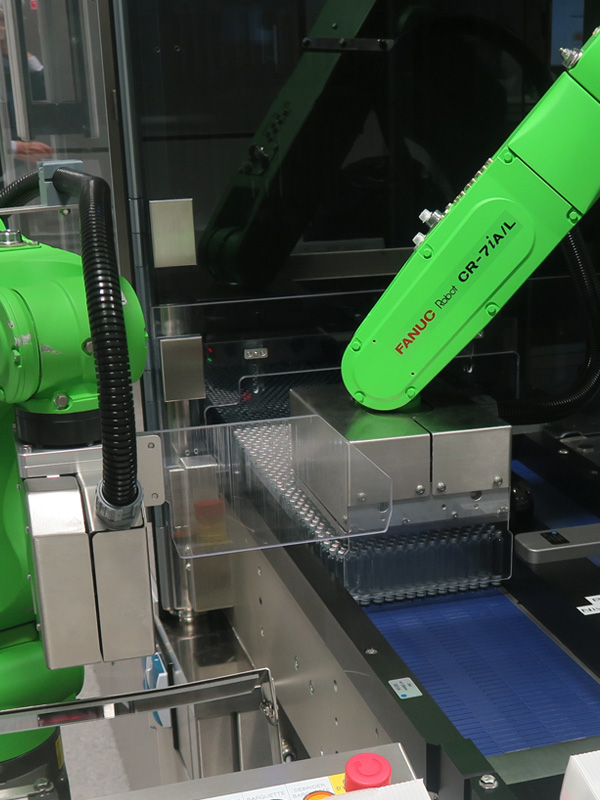

Once opened, the contents of the tray are monitored by a camera using artificial intelligence. After opening the front of the tray by an automated system, the first cobot enters the tray with a suitable tool to hold and carefully slide the glass cartridges onto the conveyor without risk of damaging them but also in complete safety for the operator who may be in the immediate vicinity.

The second cobot is responsible for continuously accompanying the cartridges positioned on the feed conveyor of the automated line. This is essential to avoid any risk of dropping the cartridges, which must not be left unsecured at any time.

Discover how our solution improves productivity while reducing the drudgery of repetitive tasks